In the intricate world of fluid control systems, gate valves stand as crucial players, providing effective control and regulation of liquid and gas flow. Their versatility and efficiency make them indispensable components in a multitude of industries. In this comprehensive article, we will delve into the fascinating realm of gate valves, exploring their design, types, applications, advantages, and important considerations for optimal usage.

|

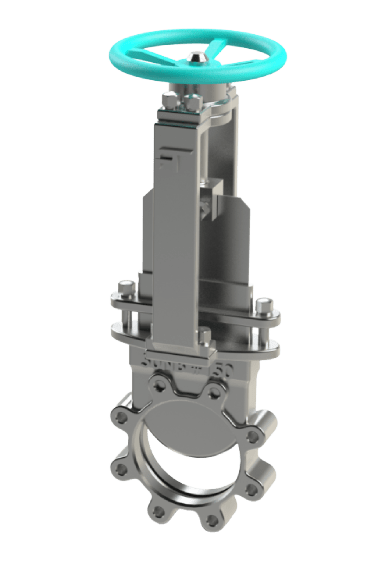

| Forged Gate Valve Manufacturer in Mumbai, India |

Understanding Gate Valves: The Basics

A gate valve is a linear motion valve that controls fluid flow through a pipe or duct by raising or lowering an internal gate or wedge. When the gate is lifted, it creates a clear passage for the fluid, allowing unrestricted flow. Conversely, lowering the gate obstructs the flow, effectively shutting off the passage.

Types of Gate Valves

1. Parallel Gate Valve:

In this design, the gate moves parallel to the direction of the fluid flow. Parallel gate valves are commonly used for on/off control applications.

2. Wedge Gate Valve:

Wedge gate valves have a gate with a wedge-shaped cross-section. This design offers a tighter seal and is suitable for applications where a tight shut-off is essential.

3. Rising Stem Gate Valve:

In these valves, the stem rises above the valve body when the valve is opened. This design allows for a visual indication of the valve's status.

4. Non-Rising Stem Gate Valve:

In non-rising stem gate valves, the stem is threaded internally, and the gate is attached to it. The stem does not rise externally during operation, making it suitable for constrained spaces.

Common Applications of Gate Valves

1. Water and Wastewater Systems:

Gate valves play a crucial role in controlling water flow in municipal and industrial water supply systems and wastewater treatment plants.

2. Oil and Gas Industry:

In the oil and gas sector, gate valves are utilized to control the flow of oil, natural gas, and other hydrocarbons within pipelines and drilling operations.

3. Power Generation:

Gate valves are essential in power plants for regulating the flow of steam and coolant in boilers, turbines, and other systems.

4. Chemical and Petrochemical Processing:

Gate valves are used to control the flow of chemicals and petrochemicals, ensuring safety and efficiency in processing plants.

5. Marine Industry:

In ships and offshore platforms, gate valves regulate the flow of seawater, fuel, and other fluids essential for operation.

Advantages of Gate Valves

Excellent Shut-Off Capability:

Gate valves provide a tight seal, effectively shutting off the flow when needed, making them ideal for applications requiring precise control.

Low Pressure Drop:

When fully open, gate valves offer minimal obstruction to the flow, resulting in a low pressure drop across the valve.

Versatility in Size and Pressure Ratings:

Gate valves are available in a wide range of sizes and pressure ratings, making them adaptable to various applications and operating conditions.

Bi-Directional Flow:

Gate valves can handle flow in both directions, providing added flexibility in installation and operation.

Key Considerations When Using Gate Valves

Material Selection:

Choose appropriate materials compatible with the fluid being controlled to ensure longevity and reliability.

Maintenance and Lubrication:

Regular maintenance and proper lubrication of the gate valve components are essential to ensure smooth operation and extend its service life.

Proper Installation:

We follow manufacturer guidelines and ensure proper alignment and installation of the gate valve to avoid operational issues and leaks.

Gate valves are powerful tools in the realm of fluid control, offering effective and precise regulation of flow. Their versatility, combined with the ability to provide a secure shut-off, makes them a cornerstone in various industries. Understanding their types, applications, advantages, and necessary considerations is essential to harness the full potential of gate valves in fluid control systems. Whether it's managing water supply, controlling chemical flow, or powering a turbine, gate valves play a critical role in keeping our world running smoothly.

.png)