Gate valves are essential components in fluid management systems, commonly used across industries like oil and gas, chemical processing, and water treatment. Their primary function is to control the flow of fluid by either allowing it to pass through or stopping it entirely. A variety of gate valves are available, each designed to meet specific operational requirements, including material compatibility, temperature, and pressure conditions. This article focuses on three key types of gate valves: API 600 Gate Valves, Forged Gate Valves, and Lined Gate Valves. Each type has distinct features that make it suitable for different industrial applications.

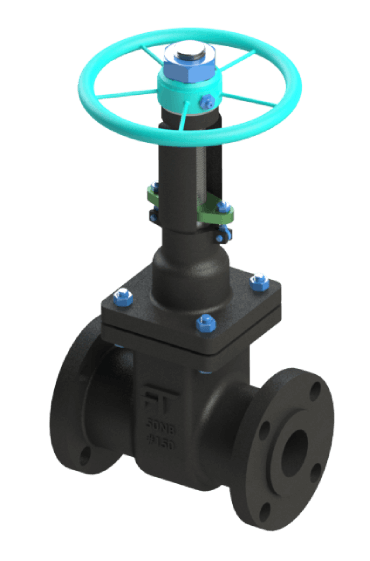

API 600 Gate Valve

API 600 is a widely recognized specification developed by the American Petroleum Institute (API) for bolted bonnet steel gate valves. Valves designed according to API 600 standards are typically used in oil refineries, petrochemical plants, and other high-pressure, high-temperature applications. The API 600 specification ensures that the valves meet stringent safety, performance, and durability criteria, making them a preferred choice in industries where reliability is critical.

|

| API 600 Gate Valve |

API 600 gate valves are often large, bolted bonnet valves that offer tight shutoff capabilities and are used in pipeline systems to either fully open or fully close the flow. These valves are generally not intended for throttling or flow regulation purposes. The primary design feature is the wedge-shaped gate that rises or falls into the valve seat, controlling the flow of the media.

Key Features of API 600 Gate Valves:

- Size Range: API 600 gate valves are available in a wide range of sizes, typically from 2 inches to over 60 inches, to accommodate different pipeline diameters.

- Material: The valves are commonly made from cast steel, offering excellent strength and durability. For corrosive environments, additional material options such as stainless steel or other corrosion-resistant alloys may be used.

- Pressure Ratings: These valves can handle high-pressure systems, typically ranging from Class 150 to Class 2500.

- Temperature Resistance: API 600 valves are designed to perform effectively in extreme temperatures, both high and low, making them versatile for various industrial applications.

The API 600 standard also ensures that these gate valves are leak-tight and meet safety standards required by regulatory authorities, making them reliable for long-term operation in critical systems.

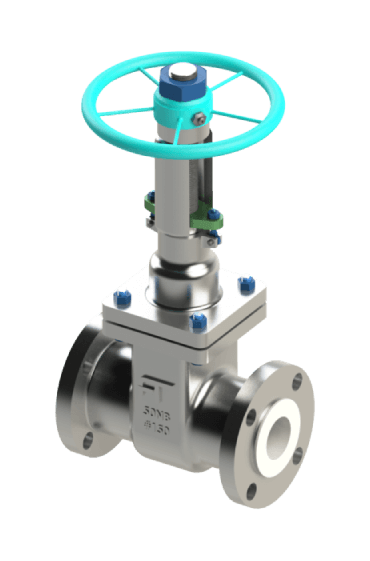

Forged Gate Valve

Forged gate valves are crafted from a single piece of forged metal, typically used in high-pressure and high-temperature applications. Unlike cast gate valves, which are made from molten metal poured into molds, forged gate valves are manufactured by mechanically shaping the metal. This forging process imparts higher strength and durability to the valve, making it less prone to structural defects like porosity or voids, which can occur in cast valves.

|

| Forged Gate Valve |

Forged gate valves are widely used in industries such as oil and gas, power generation, and chemical processing, where the operating conditions demand superior mechanical strength and resilience. These valves are ideal for applications where safety and reliability are paramount, especially in high-stress environments.

Key Features of Forged Gate Valves:

- Superior Strength: Due to the forging process, these valves exhibit greater mechanical strength, which allows them to withstand higher pressures and temperatures compared to cast valves.

- Compact Design: Forged gate valves are typically more compact than cast valves, making them suitable for installations where space is limited.

- Corrosion and Erosion Resistance: The forging process often involves heat treatment, which improves the valve's resistance to corrosion and erosion, extending its service life in demanding environments.

- High Pressure and Temperature Ratings: Forged gate valves are rated for high-pressure systems and are capable of withstanding severe temperature variations, making them ideal for power plants and refineries.

Forged gate valves can be used in severe environments where durability and reliability are non-negotiable. They are particularly favored in critical systems where even minor failure could lead to costly downtime or hazardous conditions.

Lined Gate Valve

Lined gate valves are designed to handle highly corrosive or abrasive fluids, making them ideal for industries such as chemical processing, wastewater treatment, and mining. Unlike conventional gate valves, which rely on the material of the valve body to resist corrosion, lined gate valves feature an internal lining—usually made from materials like PTFE (polytetrafluoroethylene), PFA (perfluoroalkoxy), or FEP (fluorinated ethylene propylene). This lining acts as a barrier between the corrosive fluid and the valve body, preventing chemical damage.

|

| PTFE LINED GATE VALVES |

The lining not only protects the valve but also ensures that the fluid remains free from contamination, which is crucial in industries where product purity is a key consideration. Lined gate valves are particularly beneficial when dealing with highly reactive chemicals, slurries, or acids that would otherwise degrade metal components.

Key Features of Lined Gate Valves:

- Corrosion Resistance: The primary advantage of lined gate valves is their resistance to corrosive fluids. The lining acts as a protective barrier, significantly extending the valve’s lifespan.

- Chemical Compatibility: Lined valves are compatible with a wide range of chemicals, acids, and slurries, making them highly versatile.

- Low Maintenance: The protective lining reduces wear and tear, meaning that these valves often require less maintenance compared to their unlined counterparts.

- Cost-Effective Solution: While the initial cost of a lined gate valve may be higher than a standard metal valve, the extended service life and reduced maintenance costs make it a cost-effective solution in the long term.

Lined gate valves are most commonly used in the chemical processing and mining industries, where the valves need to operate reliably under highly corrosive or abrasive conditions. Their design ensures that both the valve and the fluid remain protected from damage, ensuring consistent operation.

Gate valves are indispensable in fluid handling systems, and understanding the differences between API 600, Forged, and Lined Gate Valves is essential for selecting the right valve for the job. API 600 valves are ideal for high-pressure and high-temperature applications in oil and gas sectors, while forged gate valves offer superior strength and durability in high-stress environments. Lined gate valves, on the other hand, are designed to handle corrosive and abrasive fluids in industries like chemical processing and mining.

By choosing the correct Gate valve type, businesses can enhance the efficiency and reliability of their fluid handling systems, while also ensuring safety and regulatory compliance. For long-term success, it is important to source gate valves from trusted manufacturers that adhere to industry standards and offer high-quality products.

No comments:

Post a Comment