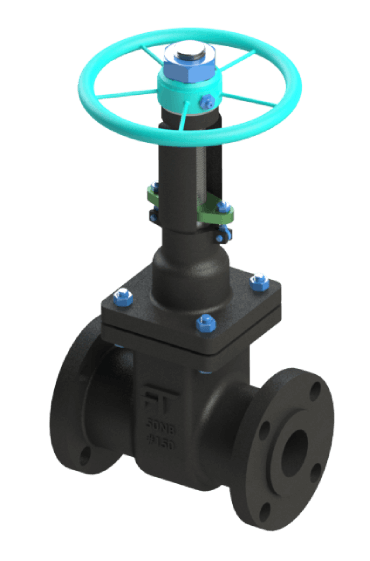

Stainless steel gate valves are essential components in industrial fluid control systems. These valves are designed to regulate the flow of liquids and gases by using a gate mechanism that moves up and down within the valve body. Known for their durability and corrosion resistance, stainless steel gate valves are widely used in industries that require high-performance and long-lasting solutions. Their ability to withstand extreme temperatures and pressures makes them a preferred choice in demanding applications.

Working Principle of Stainless Steel Gate Valve

A stainless steel gate valve operates using a linear motion mechanism. The gate, which is typically a solid metal disc, moves perpendicular to the flow direction to open or close the passage. When fully open, the gate valve allows unobstructed fluid flow, minimizing pressure drop. In the closed position, it provides a tight seal, preventing leakage. The operation can be manual (handwheel or lever) or automated (actuators). This design makes gate valves suitable for on/off control rather than throttling applications.

|

| Stainless Steel API 600 Gate Valves |

Types of Stainless Steel Gate Valves

Wedge Gate Valve

Solid Wedge: Provides strength and durability, suitable for various pressure and temperature conditions.

Flexible Wedge: Offers improved sealing by adjusting to thermal expansion and pressure changes.

Split Wedge: Ideal for handling non-uniform pressure distribution, reducing stress on the valve.

Parallel Gate Valve

Knife Gate Valve: Designed for slurry and viscous fluid applications, providing minimal clogging.

Slab Gate Valve: Used in pipelines with high flow rates and minimal pressure drop.

Rising Stem vs. Non-Rising Stem Design

Rising Stem: Stem moves up when the valve is opened, providing a visual indication of valve position.

Non-Rising Stem: Stem remains stationary while the gate moves, ideal for confined spaces.

Technical Specifications

Material: SS 304, SS 316, SS 316L.

Size Range: ½” to 24” (or more based on industry needs).

Pressure Rating: ANSI 150, 300, 600, 900, 1500, 2500.

Temperature Range: -50°C to 600°C (or as per material properties).

End Connections: Flanged, Threaded, Welded (Butt & Socket Weld).

Design Standard: API 600, API 603, ASME B16.34.

Face-to-Face Dimensions: ASME B16.10.

Testing Standards: API 598, EN 12266.

Applications of Stainless Steel Gate Valves

Oil & Gas Industry: Used in upstream, midstream, and downstream applications for pipeline control.

Chemical and Petrochemical Plants: Handles corrosive and high-temperature fluids.

Water Treatment and Desalination: Ensures precise flow control in water processing systems.

Power Plants: Controls steam and water flow in thermal and nuclear power plants.

Pharmaceutical and Food Processing: Maintains hygiene and prevents contamination in clean environments.

Advantages of Stainless Steel Gate Valves

High resistance to corrosion and extreme temperatures: Ensures longevity and reliability.

Suitable for high-pressure applications: Capable of withstanding demanding conditions.

Minimal pressure drop in fully open position: Enhances efficiency and reduces energy costs.

Long service life with proper maintenance: Reduces operational costs and downtime.

How to Choose the Right Stainless Steel Gate Valve

Considerations:

Material grade: SS 304 for general applications, SS 316 for high corrosion resistance.

Pressure class: Select based on system requirements.

Size: Choose according to flow capacity and pipe dimensions.

Temperature compatibility: Ensure the valve withstands the operating environment.

Compliance with industry standards: Verify certifications like API and ASME.

Conclusion

Stainless steel Gate valves play a crucial role in industrial applications requiring precise flow control and durability. Their robust construction and corrosion-resistant properties make them an ideal choice for high-pressure and high-temperature environments. For reliable performance and industry-compliant solutions, Freture Techno Pvt. Ltd. is a trusted manufacturer and supplier of high-quality stainless steel gate valves in India.

.png)

.png)