What are forged gate valves? Forged gate valves are specialized devices used to control the flow of liquids and gases within pipelines. Unlike traditional cast valves, which are formed by pouring molten metal into molds, forged gate valves are manufactured by shaping solid metal under high pressure. This process enhances their strength and durability, making them suitable for high-pressure and high-temperature applications.

How do forged gate valves function?

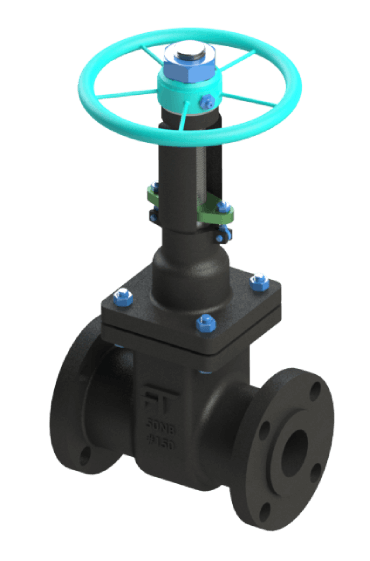

The operational principle of forged gate valves is relatively straightforward. They feature a wedge-shaped disc that is raised or lowered to either allow or block the flow of fluid. When the valve is fully opened, the disc is lifted completely out of the flow path, providing minimal resistance to the fluid and ensuring optimal flow efficiency. Conversely, when the valve is closed, the disc seals tightly against the valve seat, preventing any leakage.

|

| Forged Steel Gate Valves Manufactuirers in India |

What are the advantages of forged gate valves?

One significant advantage of forged gate valves is their robust construction, which allows them to withstand high pressure and temperature extremes. This durability makes them an excellent choice for industries such as oil and gas, power generation, and chemical processing, where reliable performance is critical. Additionally, forged gate valves typically have a longer lifespan compared to their cast counterparts, which can lead to reduced maintenance costs over time.

In what applications are forged gate valves commonly used?

Forged gate valves are utilized in various applications where fluid control is essential. They are particularly effective in on/off service, making them ideal for pipelines that require infrequent flow regulation. Common applications include power plants, oil refineries, and water treatment facilities. The ability to maintain a tight seal while handling high-pressure conditions makes these valves a preferred choice in many industrial settings.

How are forged gate valves different from other valve types?

While forged gate valves excel in applications requiring on/off control, they differ significantly from other types of valves, such as globe valves or ball valves. Globe valves are designed for throttling services and provide better flow regulation but can cause higher pressure drops. On the other hand, ball valves offer quick operation and low resistance to flow but may not provide the same level of sealing as gate valves. Therefore, the choice of valve type depends on the specific requirements of the application.

What materials are used in forged gate valves?

Forged gate valves can be manufactured from various materials, including carbon steel, stainless steel, and special alloys, depending on the application requirements. Carbon steel valves are commonly used for general applications, while stainless steel valves are preferred for corrosive environments due to their resistance to oxidation and corrosion. The selection of material significantly influences the valve’s performance, lifespan, and suitability for specific media.

How does maintenance affect the performance of forged gate valves?

Regular maintenance is essential to ensure the reliable operation of forged gate valves. Routine inspections can help identify potential issues, such as wear or corrosion, before they escalate into significant problems. It is also crucial to lubricate moving parts and replace seals when necessary to maintain optimal performance. By following a proactive maintenance schedule, operators can extend the life of their forged gate valves and reduce downtime.

What should be considered when purchasing forged gate valves?

When purchasing forged gate valves, several factors should be taken into account. The operating conditions, such as pressure and temperature, should be assessed to determine the appropriate material and design. Additionally, the specific requirements of the application, including the type of fluid being handled and the need for sealing capabilities, should be evaluated. Finally, sourcing from a reputable manufacturer ensures that the valves meet industry standards and are designed for durability and performance.

Why choose Freture Techno Pvt. Ltd. for forged gate valves?

For those seeking reliable and high-quality forged gate valves, Freture Techno Pvt. Ltd. stands out as a premier manufacturer. With a commitment to excellence and a focus on customer satisfaction, the company offers a range of forged gate valves tailored to meet diverse industrial needs. Utilizing advanced manufacturing techniques and stringent quality control measures, Freture Techno Pvt. Ltd. ensures that each valve is built to last, providing exceptional performance in even the most demanding environments.

In conclusion, forged gate valves are essential components in many industrial applications, offering reliability, durability, and excellent flow control. Understanding their features, advantages, and applications can aid in making informed decisions when selecting valves for specific projects.

Buy Forged Steel Gate Valves from Freture Techno Pvt. Ltd. to ensure high-quality solutions that meet your operational needs.

No comments:

Post a Comment